Elevators

Ensuring controlled deceleration

Installed under the elevator car, they will ensure controlled deceleration and prevent sudden, hard impacts if the car descends beyond its intended lowest floor level. Buffers are also placed beneath the counterweight as cushion in case over-traveling its normal range. This protects the elevator car and the system from counterweight collisions.

Elevator buffers are mandated by international and local safety standards, which specify their type, size, and energy absorption capacity based on the elevator’s speed and load. Regular maintenance and inspections ensure their functionality and compliance.

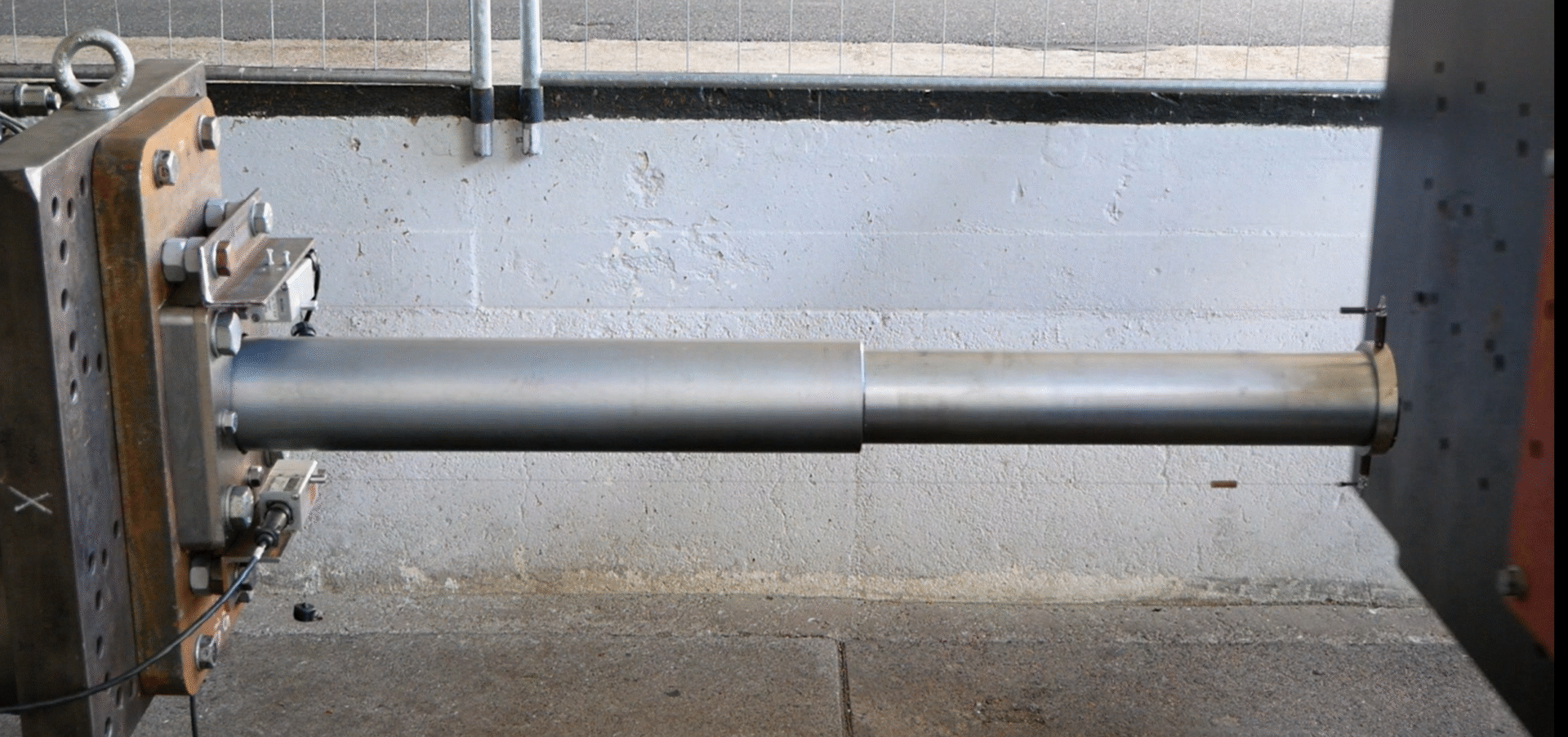

Our HYBUFF-series, gas-hydraulic buffers, are engineered and designed to absorb the kinetic energy created from high velocity and high force impact, protecting passengers, equipment and infrastructure from damage. Made from high strength steel, machined and precision engineered to meet the toughest tasks and standards for any application.

Customized and individual tuned

Each individual case has local conditions that need to be met. With our advanced energy absorption simulation software we simulate and pre-calculate the results, before designing and manufacturing customized buffers, for each application.

Drawn from the railway industry, with the highest industrial demands and standards, we have developed our Hybuff-series buffers. These are now the most used and requested units in the world from the largest manufacturers. When our buffers are installed for collision and impact protection you have peace of mind.

Long lasting lifetime

All buffer models have been exposed to extreme conditions with the harshest impact, collision, salt spray and temperature tests ensuring functionality and expected lifespan is met or exceeded. By other means – Quality is guaranteed