Gas-hydraulic buffers

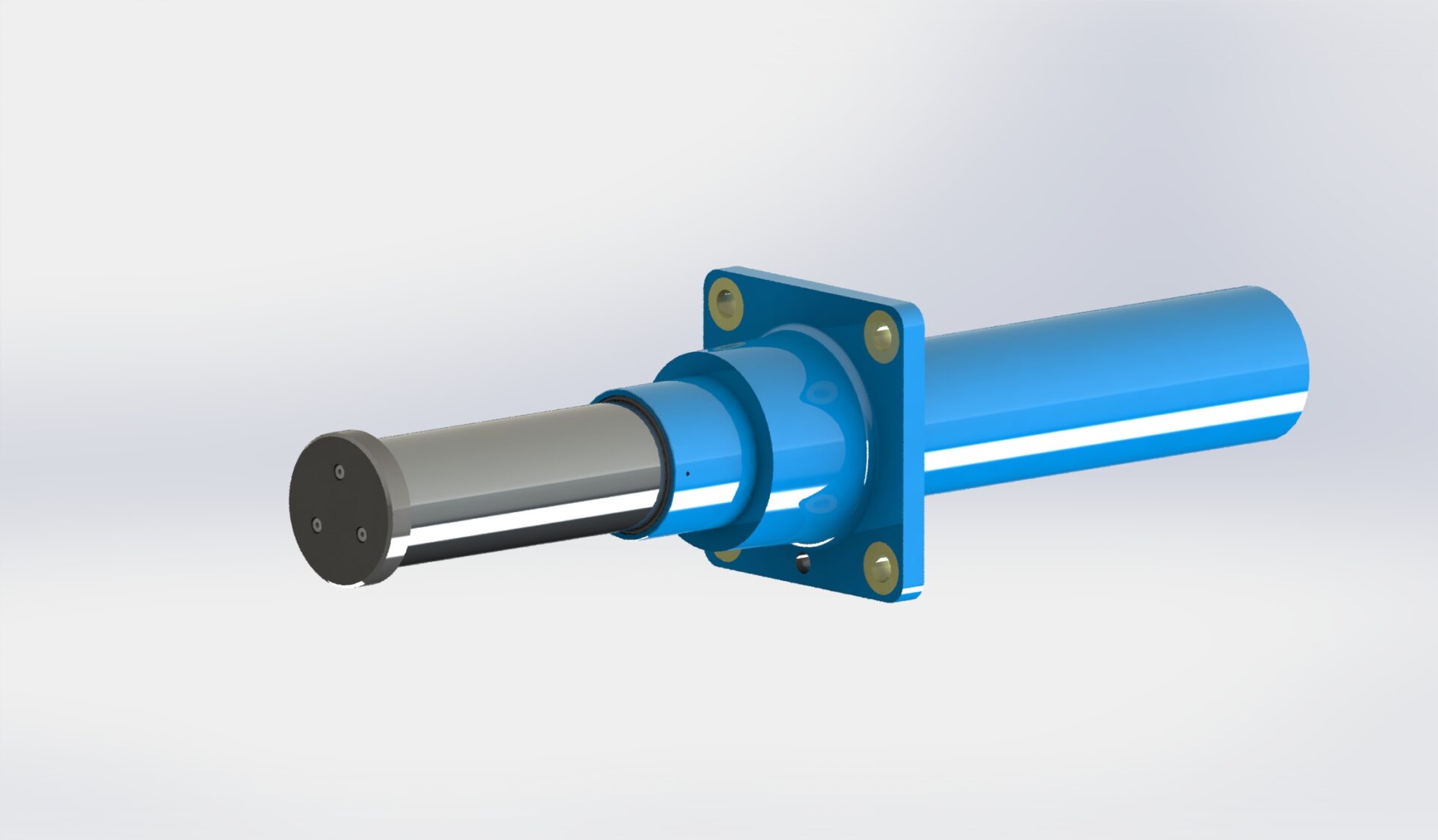

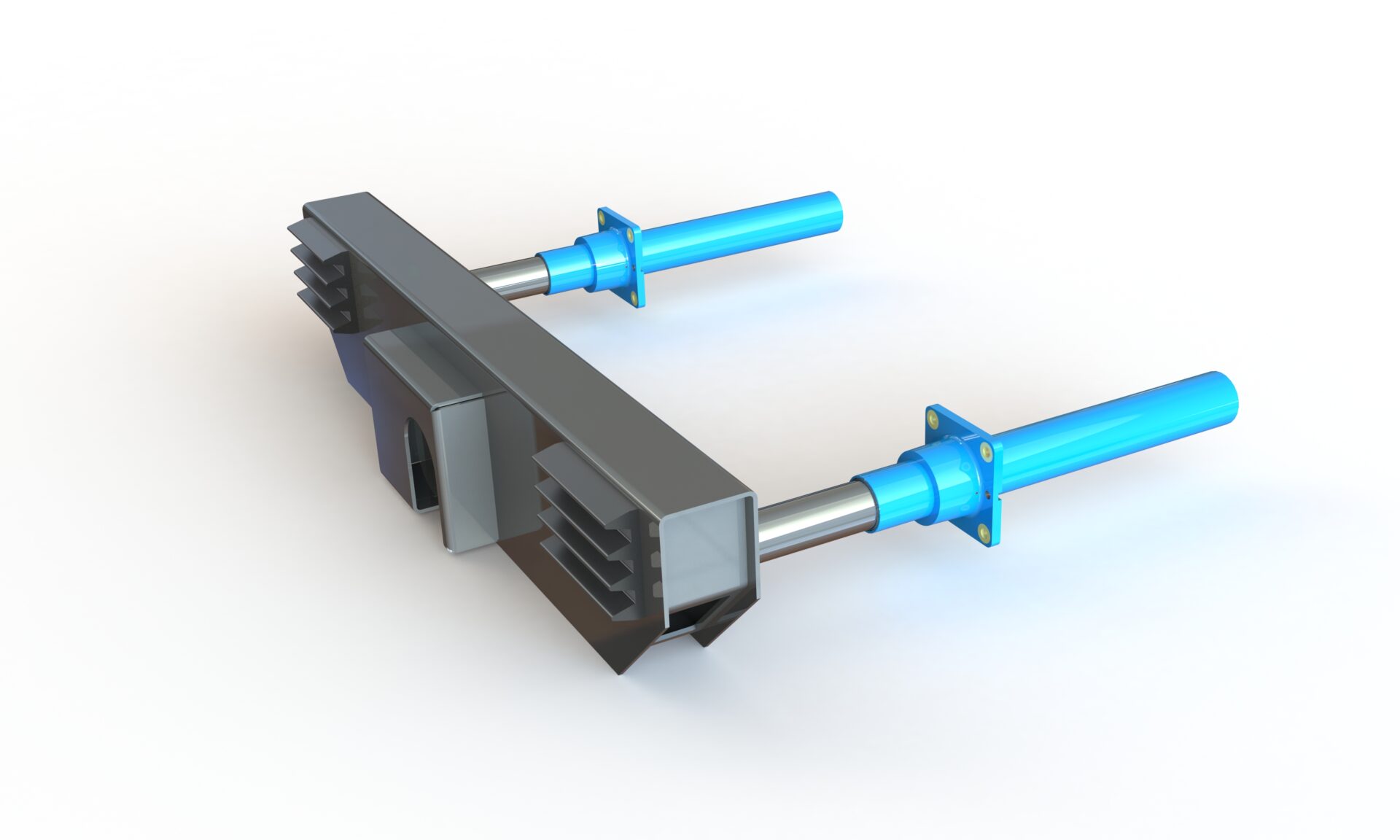

HYBUFF G-series buffers

Dellner Dampers is the world leading manufacturer of energy absorbing buffersfor stopping moving masses safely. Our HYBUFF G-series were originally designed for railway safety but are now adapted into industrial applications.

Our HYBUFF G-series buffers have been developed to give you the most cost effective solution for your energy absorption needs and will replace the most common brands on a ‘plug and play’ basis. HYBUFFs are ideal for applications where an energy stop device is needed and their robust design offers best resistance for higher forces. For the ultimate finishing touch, any color for the cylinder can be chosen within the RAL, NCS or Pantone color charts! Bellow and safety chain are available as optional extras.

Today you will find our buffers in industrial applications like buffer stops, container spreaders, crane stops, wind turbines, hydro and nuclear power stations and in defense and offshore applications.

Gas-hydraulic buffers

Gas-hydraulic buffers rely on a combination of gas compression and hydraulic damping to absorb energy efficiently. Inside the buffer, pressurized nitrogen acts like a spring, compressing when an impact occurs. At the same time, hydraulic oil flows through specially designed channels, regulating the movement and ensuring smooth deceleration. This controlled process prevents sudden stops, reducing strain on machinery and enhancing safety. The result is a highly effective system that cushions unexpected impacts and extends the lifespan of equipment and components, while also protecting people and infrastructure.

Long-lasting performance – made in Sweden

The HYBUFF G-series buffers come with optimum corrosion protection included as standard − right up to ISO EN 12944 C5M, which is tough enough for harsh sea environments. The buffers have Ni-compound treated plunger, stainless steel end cap and a front or back mount as standard.

Designs are made with the foundations of the highest requirements from the railway industry and all our new buffers are being tested and verified by third party test institutes, to ensure performance is achieved and kept. Quality guaranteed!