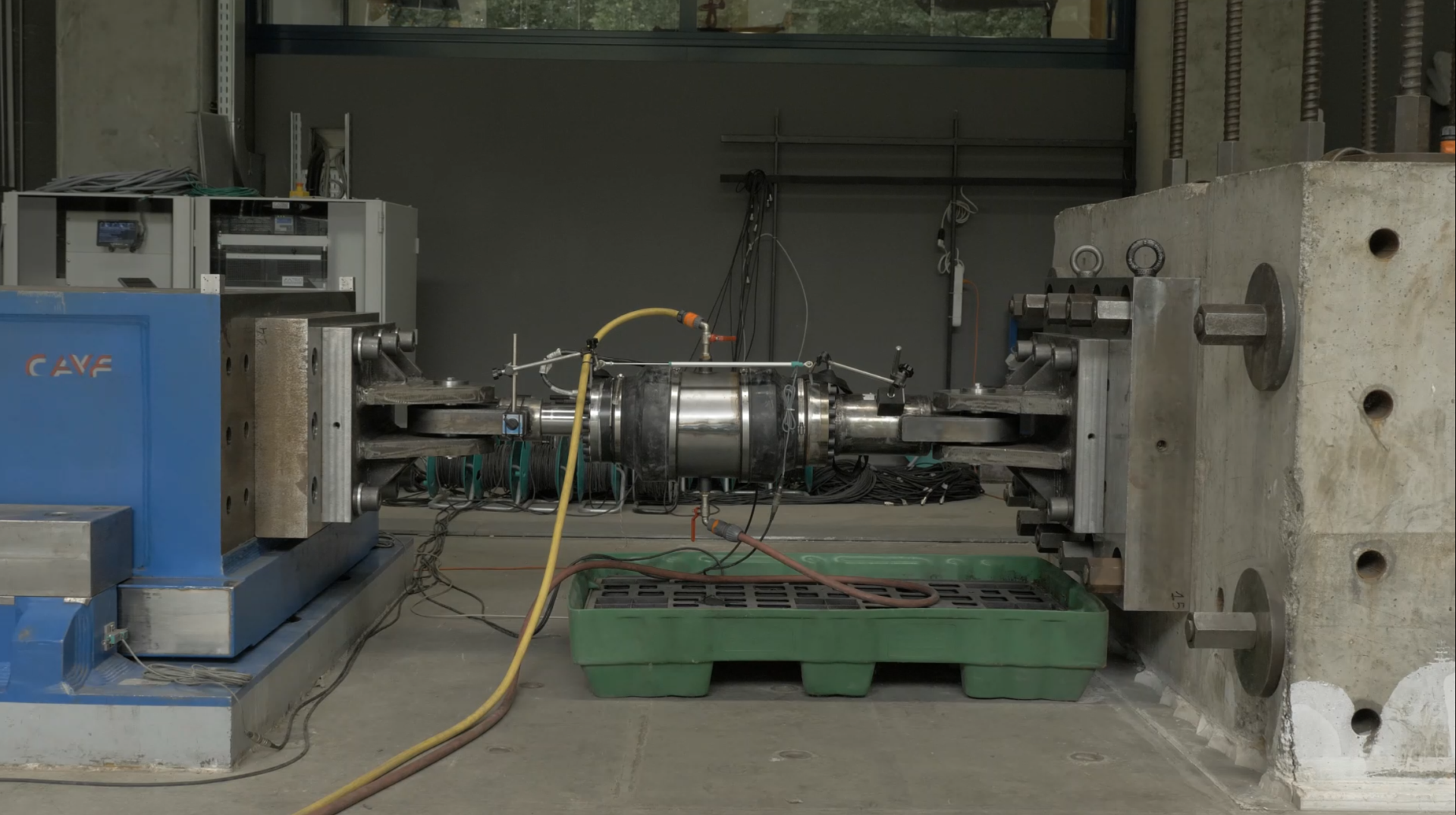

R&D, testing and verification

KNOWLEDGE IN EVERY DETAIL

The core of Dellner Dampers is our outstanding capacity to develop customized solutions and verify their function and durability prior being installed. Our in-house R&D and testing capability is the sole sponsor to our customers, when asking us to find the right solution for them.

We have produced customized damping and energy absorption solutions for customers across the globe for past 60 years. Our products increase performance, safety and comfort in applications, serving billions of people around the world daily, without their awareness. Wherever there is movement there will be a need for absorbing kinetic energy or vibration. The one job our dampers and buffers are created to do.

CUSTOMER SATISFACTION GUARANTEED

Our aim has always been to develop, design and produce the ideal solution for any vibration or energy absorption problem. And our innovative, technologically advanced products are custom built at our state-of-the-art facility in Flen, Sweden.

We work closely together with our customers to exactly understand their need for each inquiry. Our offer includes project management, R&D, design, manufacturing, testing, verification and supply of customized dampers and buffers.

Whether you want a single product, or thousands, our skilled technicians are experts at producing tailor-made, bespoke damping solutions. We will build you the right damper or buffer to perfectly match your requirements.

Simulations and engineering

Our products are custom designed according to your requirements, and sometimes, all what is needed to get started is a meeting with you and a quick drawing. For more complex applications, we have a range of advanced simulation and design tools at our fingertips and engineering expertise to solve the most challenging task.

Our engineering services includes:

- Energy absorption simulations (multi body impacts)

- Cable dynamics simulations

- FEM (Finite Element Method) calculations and FEA (Finite Element Analysis)

- LS-DYNA modelling and model validation

- CAD design in SolidWorks

- PDM-system