Quality

Thoroughly tested

All our damper and buffer products are built to last and perform reliably, even in the toughest conditions. Each unit is thoroughly tested by us and verified by external partners to ensure top quality.

They’re designed to resist fatigue, corrosion, and extreme temperatures over a long lifespan. Every product is functionally tested to meet precise damping force tolerances, and all critical measuring equipment is regularly calibrated to maintain consistent and accurate quality control.

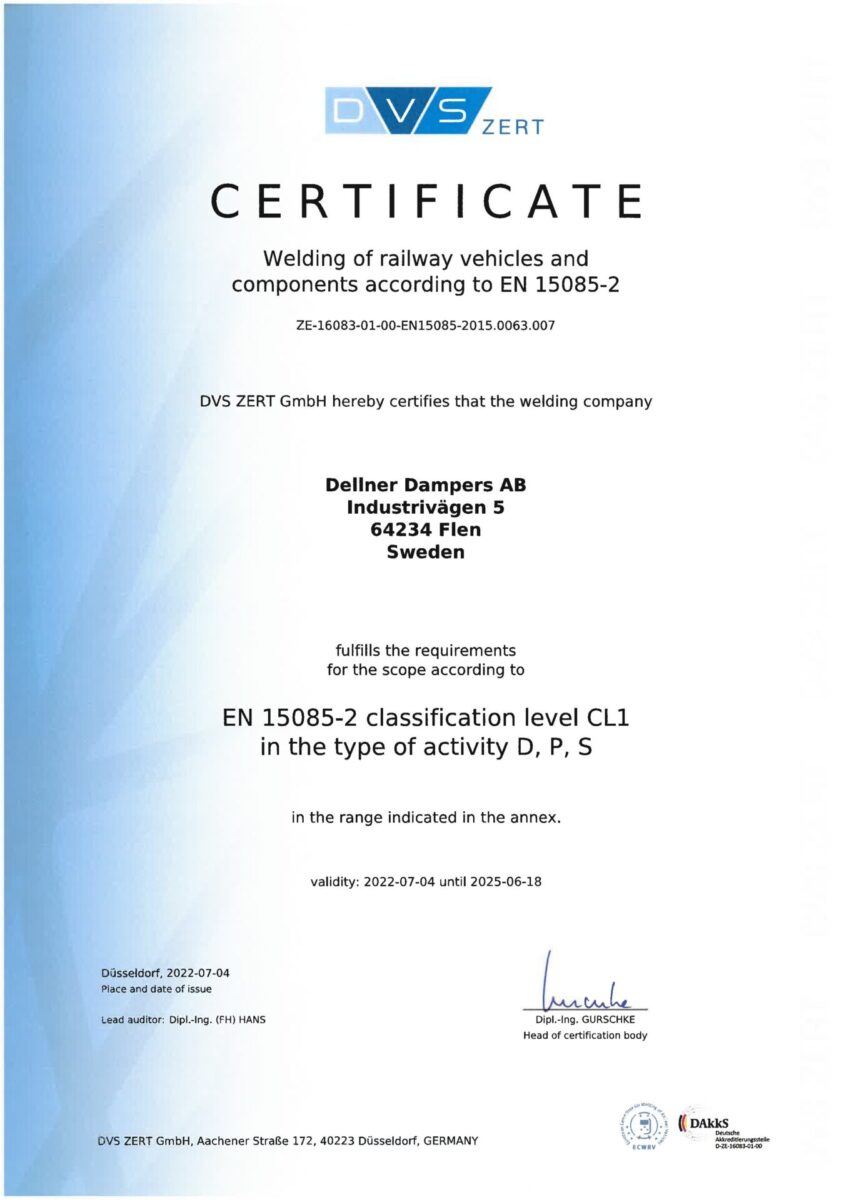

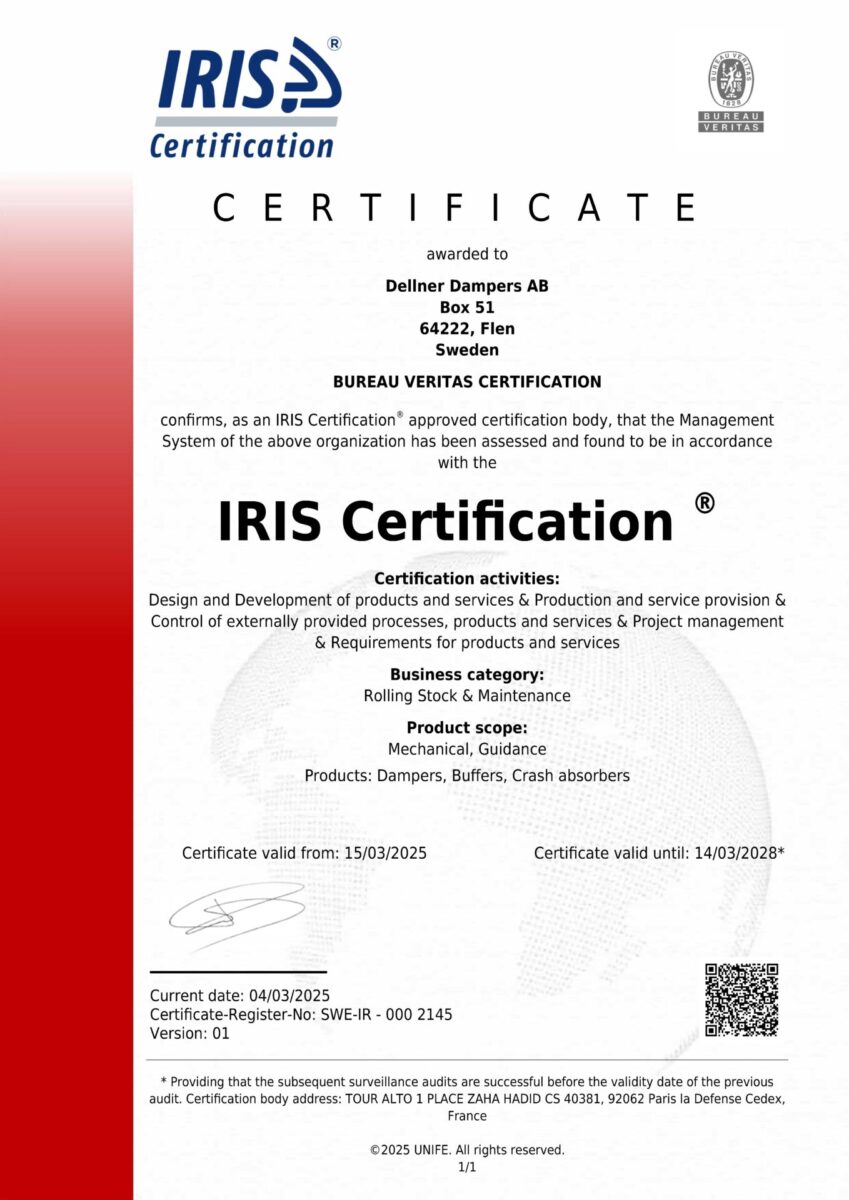

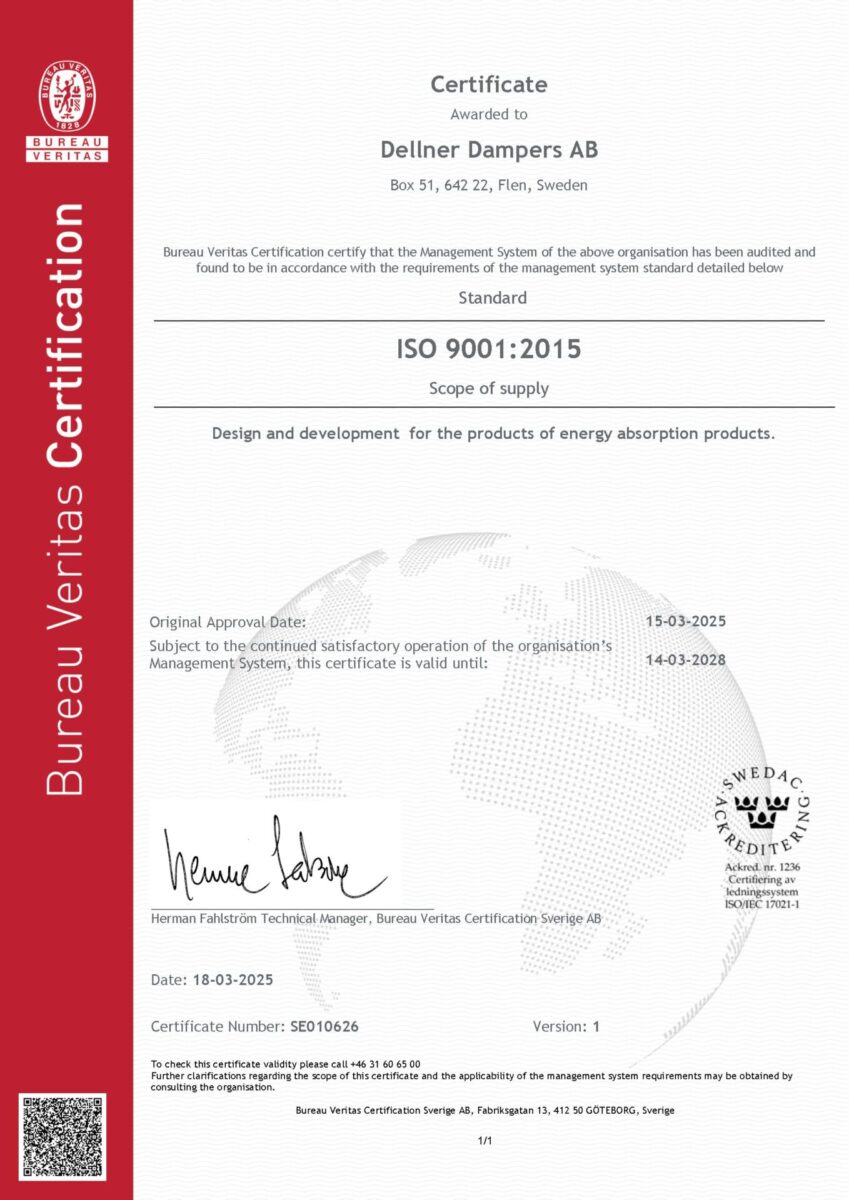

Dellner Dampers is certified according to ISO 9001, EN15085-2 CL1 (welding) and IRIS (International Railway Industry Standard – ISO 22163:2023), the new global standard for quality management systems in the railway sector. Our Anti-seismic devices, Fluid Viscous Damper ”Strucpro” which is a velocity dependent device, to use in buildings and civil engineering works where requirements on individual devices are critical, comply to regulatory requirements established by Regulation (EU) No 305/2011 and EN 15129:2009.

Safety first

Dellner Dampers products are not just designed to keep systems and structures performing flawlessly, they’re also designed to keep people safe. Without our dampers, engineering projects like bridges would be liable to fatigue, which could endanger lives.

With 60 years of experience in the railway and industrial sectors, we know that safety is paramount, and all our products are subject to strict regulations and rigorous standards. In addition to the ISO 9001 and IRIS standards, we are also certified for welding according to EN 15085-2 Level CL1 (the railway industry standard for welding), which also meets the requirements in EN-ISO 3834-2.

Certificates

Dellner Dampers is certified according to ISO 9001, EN15085-2 CL1 (welding) and IRIS (International Railway Industry Standard – ISO 22163:2023), the new global standard for quality management systems in the railway sector. Our Anti-seismic devices, Fluid Viscous Damper “Strucpro” which is a velocity dependent device, to use in buildings and civil engineering works where requirements on individual devices are critical, comply to regulatory requirements established by Regulation (EU) No 305/2011 and EN 15129:2009.